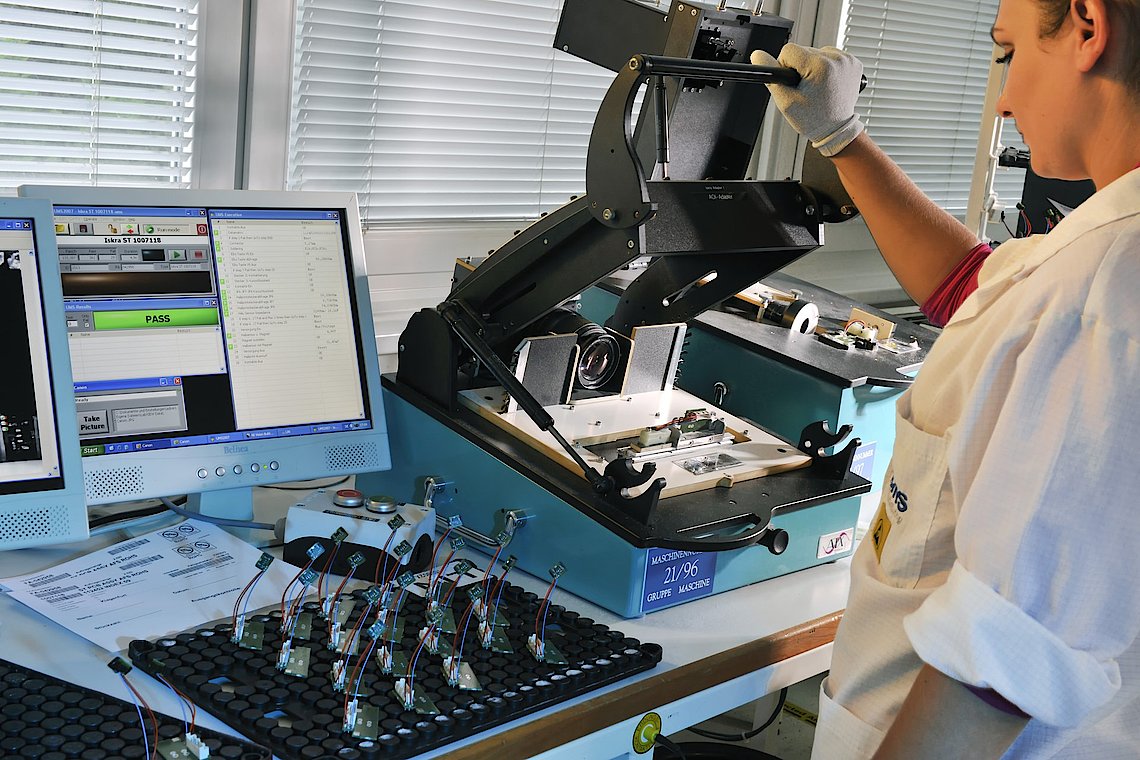

The variety of your electronics is matched by the diversity of our test planning. A raft of tests is required to guarantee that customers are supplied with high-quality, functional products.

With our Design for Testability programme we ensure from the outset that simple, cost-optimised testing of your product is possible throughout the production process.

Testing all inclusive

Our years of experience in testing is reflected in our approach. Test planning at our firm consists of four areas so we can offer testing systems individually suited to every product. They are as follows: the development of a testing strategy, the creation of a test concept, in-house construction of test equipment and performance of the various tests.